Foam adhesive for fitting roof tiles PU

1C gun foam PU for roof tiles

GUNFM-1C-ROOFTILE-PU-750ML

Register now and access more than 15,100 products

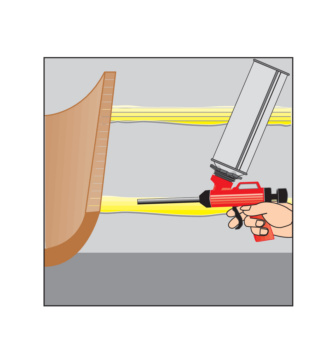

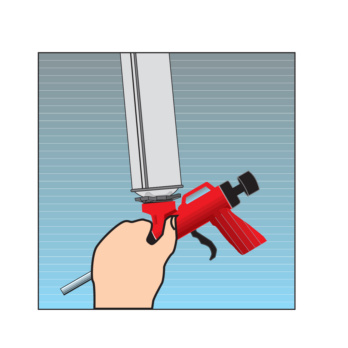

Specifically for fitting tiles and roof tiles

- Guarantees excellent sealing results even in the most extreme conditions

- Compatible with most building materials (such as concrete, tiles, roof tiles, wood etc.)

- Grey in colour, so perfectly depicts traditionally used mortar

Particularly high mechanical strength

- Particularly tough PU adhesive with high fixing power

- Higher tensile strength than commonly used systems

- Exceptional resistance to atmospheric agents (e.g. wind etc.)

- Cannot be damaged by insects, parasites, moulds or fungi

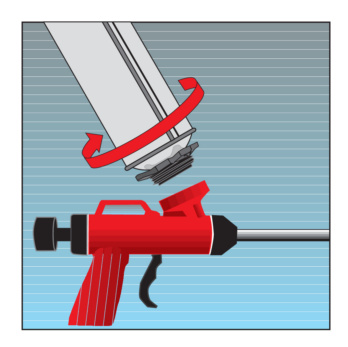

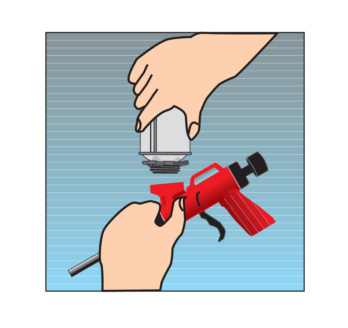

Revolutionary mounting system

- Significant savings in time, labour and money

- Speed and practicality when executing the work

- Easy handling combined with increased operational safety

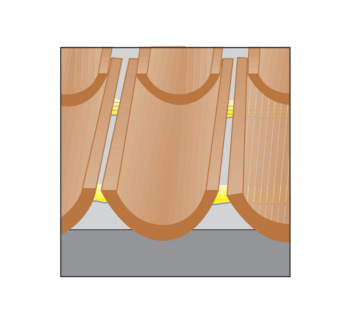

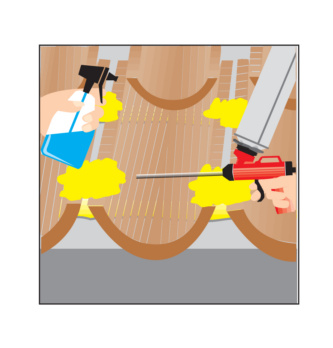

The adhesive almost doubles in volume

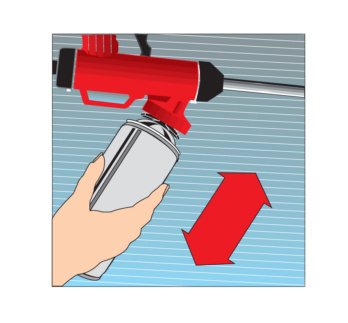

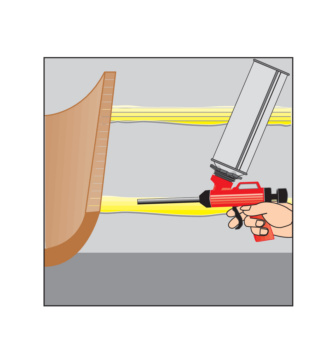

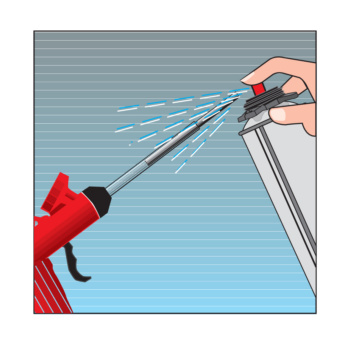

After application, use the appropriate cleaner to thoroughly clean all parts of the gun that are coated with fresh PU adhesive

Leave any cylinders that are not completely empty attached to the gun for max. 1 week

Clean up any residues of uncured adhesive with the cleaner

The hardened adhesive can be removed with the special cleaner

The product does not adhere to polyethylene, PTFE, silicones or surfaces treated with release agents

Does not contain formaldehyde

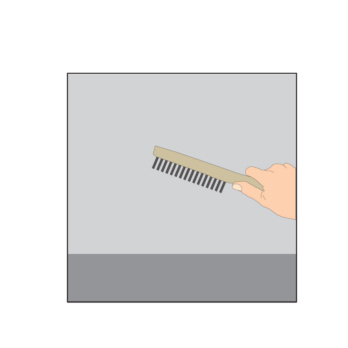

Dampen the surfaces with water before applying the adhesive and dampen each layer of adhesive during and after application

While the technical advice given is based on our experience and should be followed, it is purely indicative and must be confirmed through extensive practical tests. This does not relieve the purchaser of their responsibility to personally test our products to see whether they are suitable for the intended use

Datasheets(X)

Suitable for fitting roof tiles. Can be applied to plaster, concrete, wood, stone, metal etc.

Chemical basis | Single component polyurethane |

Colour | Grey |

Smell/fragrance | Characteristic |

Moulded density | 15 kg/m³ |

Conditions for moulded density | at 20°C and 60% relative humidity |

Tack-free after | 10 min |

Conditions for being tack-free | at 20°C and 60% humidity |

Can be cut after | 18 min |

Conditions for ability to cut | at 20°C and 60% relative humidity |

Full resilience | 8 h |

Conditions for full resilience | at 20°C and 50% relative humidity |

Min. processing temperature | 5 °C |

Max. processing temperature | 35 °C |

Min. surface processing temperature | 5 °C |

Max. surface processing temperature | 35 °C |

Min. processing temperature for can | 5 °C |

Max. processing temperature for can | 25 °C |

Min. temperature resistance | -40 °C |

Max. temperature resistance | 90 °C |

Building material class | B3 - Of high flammability |

Building material class conditions | in accordance with DIN 4102 |

Heat conductance λ | 0.04 W/(m*K) |

Water absorption (%) | 0.3 Vol-% |

Water absorption conditions | in accordance with DIN 53433 |

Min. tensile strength | 18 N/cm² |

Conditions for tensile strength | in accordance with DIN 53430 |

Ultraviolet resistance | No |

Breaking elongation | 30 % |

Breaking elongation conditions | in accordance with DIN 53430 |

Shear strength | 8 N/cm² |

Yield (volume) approx. | 40 l |

Contents | 750 ml |

Container | Aerosol can |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | upright, cool and dry storage area |

| Technical data: | |

| Optimal application conditions | +20°C, 60 % relative humidity, moisten well before, during and after use |

| Made with expanded foam in the joint | Up to 60 linear metres in a 2.5 cm diameter joint |

| Dust dry | After approx. 6-10 minutes* |

| 10 % elastic modulus (DIN 53421) | 5 N/cm2 |

| Class according to DIN 4102 | B3 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!