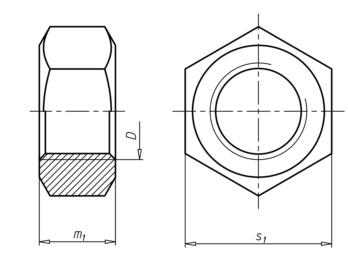

Hexagon nut DIN 934, steel I10I, GEOMET 321 A + PLUS VL

DIN 934 steel I10I zinc flake silver Geomet 321

NUT-HEX-DIN934-I10I-WS19-(GE3A/VL)-M12

Art.-no. 01021 12

EAN 4056807632124

Register now and access more than 15,100 products

The GEOMET 321A + PLUS VL coating is a non-electrolytic, aluminium-grey, thin-layered coating consisting of zinc and aluminium flakes together with a transparent top coat.

- Layer thickness: 6-8 µm

- Friction coefficient: 0.09–0.14

Advantages of the GEOMET 321A + PLUS VL coating:

- Contains no chromium VI and no other materials that are hazardous to health

- Fulfils EU directive on end-of-life vehicles. Very high corrosion resistance >=720-h salt spray test according to ISO 9227/DIN 50021 (in comparison to yellow zinc-plated A2C – 72 h)

- Resistance to automotive fuels and fluids (standard fuels, diesel, engine oil, coolant etc.)

- Environmentally friendly, water-based

- Resistant to contact corrosion

- Heat resistance at least 300°C

- Excellent paint adhesion

Hexagon nuts complying with the DIN 934 standard cannot support test loads as per DIN EN ISO 898-2.

- The strength class designation has two vertical bars added before and after the strength code to differentiate.

DIN 934 has been withdrawn and replaced by ISO 4032/8673. There is no similarity (nominal Ø changed | Some nut heights changed | Width across flats changed for M10, M12, M14, M22 | ISO 4032 for standard thread | ISO 8673 for fine thread).

Datasheets(X)

CAD data (available after login)

| |

Thread type x nominal diameter (D) | M12 |

Height (m1) | 10 mm |

External drive (s1) | WS19 |

Standards | DIN 934 |

Material | Steel |

Property class | I10I |

Surface | Flake zinc silver |

RoHS-compliant | Yes |