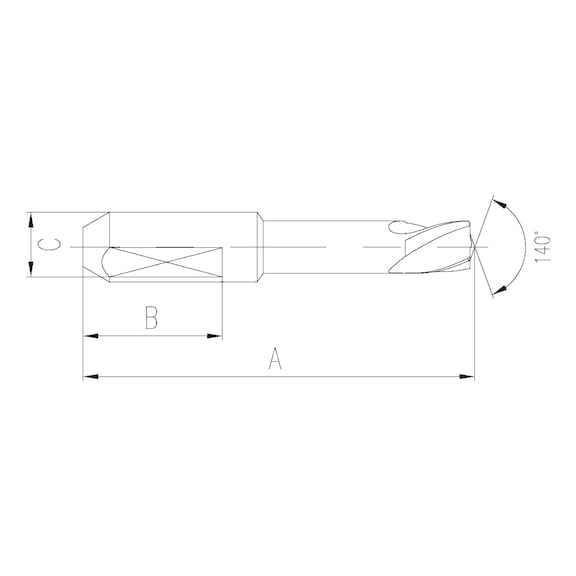

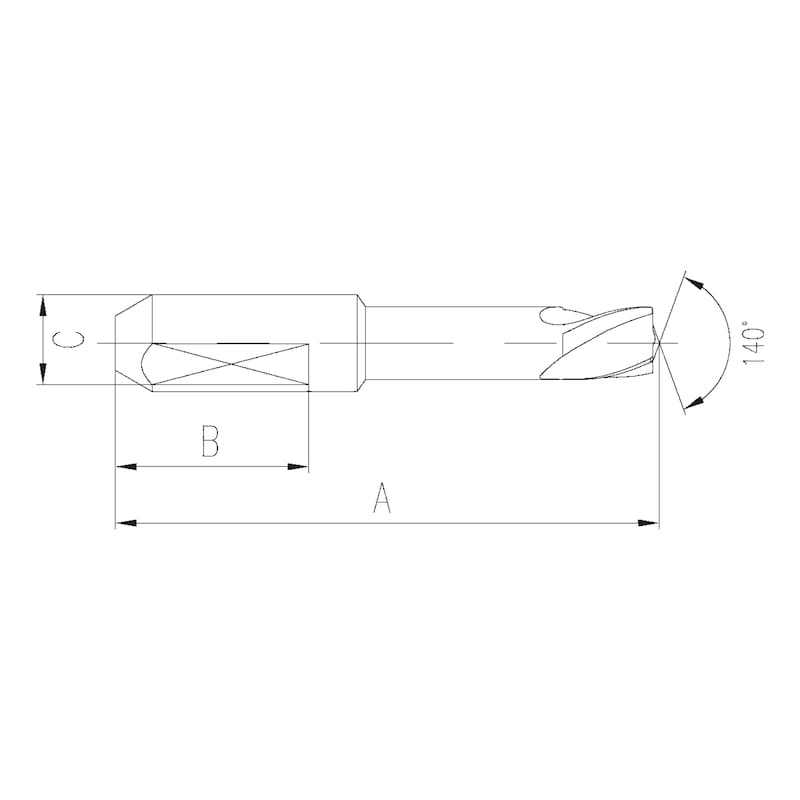

Solid carbide spot-weld drill bit with three cutting edges

The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

Solid carbide spot-weld drill bit with three cutting edges

For drilling out/milling spot welds on car bodies with high-tensile steel plates in all types of cars on A-pillars, B-pillars, door sills etc.

Show availability in Würth Portugal trade store

In order to check the stock in a Würth Portugal branch, please log in.

If you have any questions, please call our service hotline at +351 211 989 840.

You are not yet a Würth Portugal customer or do not yet have access data to the Online Shop? Then register now in just a few steps. After a successful check of the entered data, you will have immediate access to the stock inquiry as well as all prices and can immediately order.

Exclusively for trade customers

Register now and access more than 15,100 products

Variants

Exclusively for trade customers

Register now and access more than 15,100 products

Call customer service: +351 211 989 840

Prices for customers after login

Excellent centring of the drill bit on the spot weld

Wide yet robust tip geometry

Extremely long service life

Innovative Magma coating on the drill tip

Application area

- Can be used with Spitznagel drill devices and the Wieländer & Schill Vario Drill and all three-jaw chuck drills.

Instructions

- Solid carbide is extremely hard, making it very brittle and prone to breaking if not handled correctly.

- Position the drill bit precisely and at a right angle. Place the drill bit in the centre, then start drilling, making sure that you apply contact pressure evenly.

- We recommend drilling at a consistent speed, at a maximum of 1800 rpm.

- The following must be avoided: interrupted cuts, forcing the drill bit, jolting the drill bit sideways and dropping the drill bit.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!