For detailed information, other images and documents, please select individual articles from the following table.

Urea glue E1

Self-curing resin powder with low formaldehyde emission for hot-gluing of wooden surfaces

Register now and access more than 15,100 products

Variants

Register now and access more than 15,100 products

- Self-hardening urea glue in powder form, excellent solubility

- Long open time and long pot life

- Good resistance to water and solvents to limit problems with bubbles during the painting stage

- Low bleeding on the veneer surface

- High adhesiveness

Only with a maximum coating of 100 g/m² does the manufactured product fall within formaldehyde emission class E1

* The times should be increased by 1 minute for every millimetre of thickness

Rigid-tough adhesive line. If the underlying material is not rigid veneer, there may be cracking, particularly when wet

Caution with woods containing tannin!

Storage below +5 °C or above 35 °C can cause problems with the product

While the technical advice given is based on our experience and should be followed, it is purely indicative and must be confirmed through extensive practical tests. This does not relieve the purchaser of their responsibility to personally test our products to see whether they are suitable for the intended use

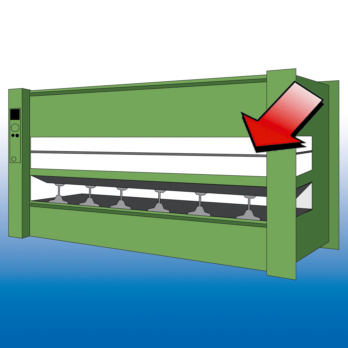

The product must be used only with a hot press and is ideal for producing veneers with most common wood types, producing solid wood panels and composite wood panels (chipboard, MDF, multilayer etc.) and producing honeycomb panels

Suitable for indoor furniture, where occasional exposure to water or condensation is possible

Mix the resin in non-metallic containers with cold water (15-20 °C) in the weight ratio: 2 (resin) to 1 (water) or in volume ratio: 4 (resin) to 1 (water). Dispersion is carried out by stirring, adding half the water needed to the resin until the product has no lumps. Then add the remaining water and shake until fully dispersed. Spread the glue using an adhesive applicator roller, art.0891186 + art.0891188 or a brush. The quantity must be dosed between 100 and 200 g/m2 depending on the porosity of the underlying material. Before the hot pressing, ensure that the glue is moist and sticky. Hard and resinous woods such as birch, ash, burr or tropical woods such as teak,

rosewood, acacia etc. may require special formulations. Add D3 vinyl glue with variable percentage from 10 % to 30 % depending on the type of work and

wood. Do not add vinyl glues when bonding cherry wood. Preliminary tests must be carried out before proceeding with the bonding

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!